At Forcys, we understand that modern maritime security demands more than just sophisticated sensors or autonomous vehicles – it requires seamless integration of cutting-edge technology. This is where the combined expertise of our technology partners comes into play. The capabilities of EIVA’s ViperFish, alongside advanced solutions from Sonardyne, and Wavefront Systems are reshaping how subsea threats are monitored and managed, ensuring that the maritime defense community has the tools needed for effective real-time operations.

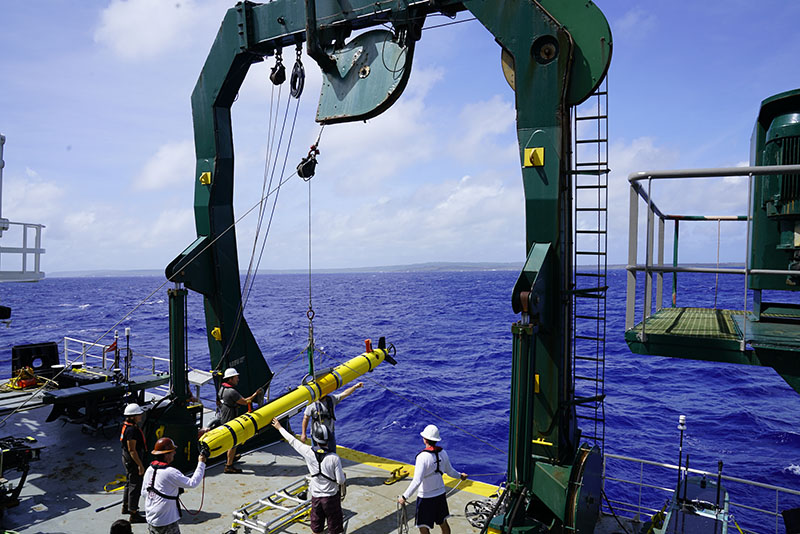

ViperFish is an all-in-one remotely operated towed vehicle (ROTV) designed for high-resolution data collection in autonomous operations. At Forcys we see the integration of this product as a significant step forward in autonomous operations. Designed for seabed imaging and geophysical surveys, ViperFish performs these tasks with remarkable precision, particularly and can even be paired with unmanned surface vessels (USVs). This opens up new possibilities for autonomous operations in complex underwater environments, enhancing mission safety, efficiency and data accuracy.

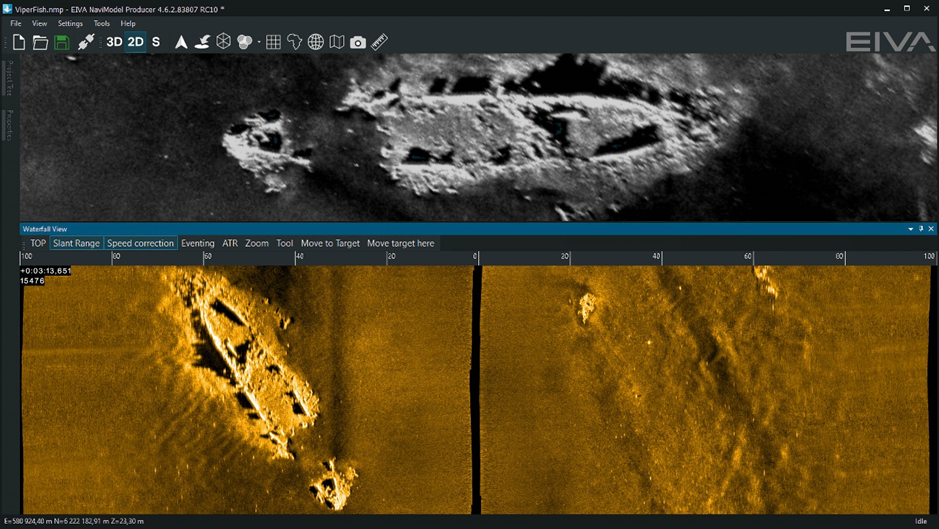

By combining this ROTV with positioning systems, sonar technology and EIVA’s NaviSuite survey software, we deliver a powerful, integrated solution that supports critical defense missions. ViperFish’s ability to automatically maintain a set height above the seabed makes it an invaluable tool for mine countermeasures, UXO (unexploded ordnance) surveys, and rapid environmental assessments.

“Forcys leverages Covelya Group partnerships to deliver solutions that provide capabilities beyond the sum of their individual components,” says Antonio Belfiore, Senior Sales Manager at Forcys. “Additionally, the combined research and development expertise across our group of companies enables Forcys to rapidly adapt to emerging threats and evolving mission requirements. This know-how was instrumental in the development of ViperFish. Designed to be the tool of choice for mine-hunting across the littoral and in riverine environments, Viperfish is also easy to use and provides your team actionable data in real-time.”

In the context of mine warfare, these integrated solutions are revolutionizing the way threat detection is carried out. By relying on autonomous vehicles that can navigate complex underwater environments with precision, defense teams can carry out missions more efficiently and frequently than ever before. The combination of ViperFish’s flexibility and the advanced sensor technologies it brings together enables vast subsea areas to be covered with unprecedented detail.

These advancements not only improve operational efficiency but also provide the necessary foundation for many future maritime and defense security operations.

At Forcys we’re proud to be part of this journey, ensuring that autonomous technology plays a central role in securing your assets.

Read more about our technology partner EIVA.

Discover ViperFish ROTV deployed by ProZero 8m Naval Intelligence USV:

Forcys, a global leader in underwater defense technology, and Cubedin, an innovator in modular infrastructure for maritime operations, are proud to announce a strategic partnership to provide rapidly deployable modular MCM solutions. To this end the companies have entered a Memorandum of Understanding (MoU) signed at EURONAVAL 2024 in Paris.

Forcys integrates and brings to the defense market world-changing solutions from leading technology partners Chelsea Technologies, EIVA, Sonardyne, Voyis, and Wavefront Systems. Forcys will harness these capabilities to deliver highly customizable, interoperable, and containerized solutions for complex naval missions.

At the core of this integration is Forcys’ MCM-in-a-box, designed and developed by EIVA. The 20-foot Cube module solution features EIVA’s Remotely Operated Towed Vehicle (ROTV). This versatile system supports a variety of payloads, enabling it to meet Mine Countermeasures (MCM) requirements as well as Rapid Environmental Assessment (REA), and Intelligence, Surveillance, and Reconnaissance (ISR) operations.

Designed with maximum flexibility in mind, the MCM-in-a-box can operate as a standalone system from any vessel of opportunity or military ship, and it is ideally suited to the Cubedin concept. “We are excited to partner with Cubedin and see our MCM-in-a-box solution incorporated into Cubedin’s modular concept,” said Antonio J. Belfiore, Senior Sales Manager EMEIA at Forcys. “This integration will make it easier to incorporate our solution into more complex C2 setups, creating seamless integration opportunities for modular military ships and making our systems readily accessible to our customers.”

Multi-Aperture Sonar (MAS) systems have been designed to deliver high-frequency, high-resolution, and long-range imaging data to improve the probability of detection of unexploded ordnance (UXO), mine-like objects, and improvised explosive devices (IED) while minimizing the probability of false alarms.

MAS outperforms traditional side-scan in virtually all underwater environments and is also known to deliver data approximating synthetic aperture sonar (SAS) at a fraction of the power required. Where MAS truly comes into its own is when operating in shallow to very shallow waters (SW, VSW) across the littoral. In these waters, the acoustic environment is particularly hostile. The output from traditional side-scan and synthetic apertures sonars (SAS) is affected by higher order multi-path reverberation, unstable velocity of sound profiles, often unknown, as well as significant bathymetry, baseline decorrelation effects and platforms that are unstable. The result is far less reliable end sonar products with greater impact to longer range systems. This is particularly acute in tidal and riverine environments.

However, the ease of MAS operations is not to be underestimated when planning a deep-water campaign. Effective operations save time and money.

Because MAS is simple to operate it can be easily integrated into your application. The following are just a few examples in the public domain that illustrate where Solstice MAS from our technology partner Wavefront Systems has been integrated:

- Viperfish ROTV: This remotely operated towed vehicle manufactured by our technology partner EIVA, has been specifically designed to deliver a next-generation mine hunting capability to unmanned surface vessels.

- L3Harris Iver 4 AUV: As part of a combined module with Voyis insight optical systems providing a one of a kind classify and identify capability.

- The Triton from Ocean Aero: This hybrid platform capable of sailing to a remote location and diving to acquire high quality seabed data. Read more here.

- Autosub Long Range AUV: A long range autonomous underwater vehicle manufactured by the National Oceanographic Centre. Find out more by following this link.

- Bluefin-9 and Bluefin-12 AUVs from GDMS: Equipped as standard and chosen to support the Royal Australian Navy’s SEA 1778 program.

- Seasword 2 USV: Selected Solstice as payload to deliver an MCM capability. For more information visit this news site.

- Double Eagle SAROV from SAAB: An MCM power horse, used to provide on stride classification, identification and neutralization capabilities.

Some key differentiation is follows:

- Performance to power ratio: No other system produces highly detailed mine-hunting data while hardly making a dent on the hotel load of the host platform.

- Performance in shallow waters: In depths of up to 30 m depth, SAS or lower frequency side-scans can be affected by multipath effects from the surface and seafloor. For some SAS systems these effects can compromise as much as 50% of their swath. For Solstice, the impact will typically be less than 10%.

- Simpler to operate: Unlike SAS, Solstice is simple to plan for as the range remains constant regardless of vehicle speed. There is no risk of a data holiday caused by sudden accelerations from currents. The result is more predictable and simpler to manage surveys.

Did you know that a version of Solstice exists that doubles the along-track resolution. The S4000 is longer and consumes more power, 37 W including on-board real time processing, but delivers improved performance to support identification of smaller targets across the whole 200 m swath.

If you would like to find out more please don’t hesitate to get in touch.

Forcys is excited to announce they have been selected by Ocean Aero as a payload provider for their world-leading autonomous underwater and surface vehicle (AUSV), the Triton.

The Triton is the world’s only environmentally powered AUSV. Completely solar and wind powered, it can travel at speeds of up to 5 knots and can submerge for up to 5 days at 2 knots.

A true multi-domain workhorse, the Triton can be used as a force multiplier for defense operations, offering easy logistics, launch, and recovery while evading detection using autonomous avoidance and deep diving capabilities.

Forcys will be supplying Ocean Aero with SPRINT-Nav Mini, the world’s smallest hybrid acoustic-inertial navigation technology from its technology partner Sonardyne and Solstice, the leading multi-aperture sonar (MAS) for Autonomous Underwater Vehicle (AUV) systems, from its technology partner Wavefront Systems.

Forcys’ General Manager and Head of Global Sales, Dan Zatezalo welcomes their selection: “We are thrilled that Ocean Aero has chosen us as their payload provider for defense applications. Their revolutionary technology is a great complement to our offer, and we think their customers are going to love the results. We look forward to working with them in driving the autonomous ocean defense technology sector forward.”

Bob Marthouse, COO from Ocean Aero said; “A key differentiation in our selection process is the performance to power ratio. We need to maximize the value from our payloads while managing the power consumption to sustain our mission goals. This is where the technology from Forcys makes a significant difference. On our last mission, everyone was highly impressed with the Solstice MAS.” With Forcys’ marine defense market expertise, alongside its access to many technology partners, and Ocean Aero’s many applications for the Triton, the partnership looks set to be a revolutionary and fruitful one.

Explosive ordnance, such as mines, pose a significant threat to naval operations, offshore energy projects, and other maritime activities. Traditional methods of disposing of these hazards often put personnel and equipment at risk as they require divers or remotely operated vehicles (ROVs) to approach the ordnance closely and manually initiate the detonation process.

The Initiation Transponder 6 (IT 6) from our technology partner Sonardyne, when integrated with mine neutralization devices mounted on a VideoRay Mission Specialist Defender underwater robot, provides a remote, autonomous, safe and effective solution for mine clearance operations. This technical collaboration allows for acoustic initiation and detonation from a remote location, eliminating the need for and risks associated with physical proximity to the ordnance.

The integration of the Defender and mine neutralization devices with the IT 6 represents a significant advancement in the field of explosive ordnance disposal (EOD).

How it works:

- The IT 6 is connected to a non-electric mine neutralization device, which is deployed near the contact by the Defender.

- Once the neutralization device is in place, the Defender can be maneuvered to a safe distance, typically around 1 kilometer away.

- Using Sonardyne’s Wideband 2 digital signal technology, the IT 6 receives an acoustic command to arm the charge from a surface vessel or command center. A subsequent command then initiates the shock tube and detonates the neutralization device.

- The entire process can be carried out in most weather conditions and during day or night, enhancing operational flexibility and safety.

Benefits:

- Enhanced safety: By eliminating the need for physical proximity to the contact during detonation, the combination of the IT 6 and Defender significantly reduces the risk to personnel and assets.

- Increased operational efficiency: The autonomous delivery and wireless initiation capability streamlines the process, allowing for faster and more efficient mine clearance operations.

- Versatility: The IT 6 and Defender can be used in various underwater environments, including deep-water operations, making it suitable for a wide range of clearance missions. The underwater robot is designed for more precise control of the vehicle position and orientation, heavier payloads and demanding interventions. With seven thrusters, it can move in any direction and maintain active pitch to face its target in an upward or downward orientation.

- Proven technology: Sonardyne’s Wideband 2 digital signal technology draws on a fifty-year heritage; it is field-proven, ensuring reliable and long-range underwater wireless communication. The Defender draws on VideoRay’s twenty-five years of ROV design experience and is built with power, reliability and flexibility in mind.

- Multi-shot: the IT 6 can be fired multiple times, making deck tests and practice runs affordable. In addition, if a mission is aborted the kit can be safely recovered and reused. The explosive charge and the IT 6 are only sacrificed on confirmed contacts.

- Cost: Once the initial investment has been made for the technology, the cost per deployment is significantly lower than sending personnel on each mission. If multiple ROVs are deployed, they can be controlled from one vessel or control room, thus further reducing costs.

Demonstration

In 2022, the IT 6 and the Defender were demonstrated together for the first time to the UK’s Defence Science and Technology Laboratory (DSTL) and the UAE Navy at a quarry in Wales.

The demonstration included successful detonations of a mine neutralization device, delivered by the Defender and initiated by the IT 6, from a range of approximately 1 kilometer.

As armed forces around the world move towards more autonomous operations on land, in the air and under the sea, there will be increased demand for the utilization of existing and the development of new technology.

The benefits in terms of safety, efficiency, adaptability and cost are obvious, not just in mine countermeasures; and the collaboration between market leaders, such as Forcys, Sonardyne and VideoRay, will be at the forefront of driving advances in the technology. Contact us to see how we can help you be there too.

_______________________________

Did you know that another of our technology partners, Voyis, manufacture the market’s technically leading ROV piloting camera? The Discovery camera from Voyis enhances your identification by delivering crisp 4K images of your targets in real-time. The ideal complement to the IT 6 and Defender. Find out more in a blog coming soon…

The ViperFish is an all-in-one compact remotely operated towed vehicle (ROTV) ideally suited for expeditionary mine countermeasures (MCM) and explosive ordnance disposal (EOD) surveys. Martin Kristensen, VP of Hardware Development at our technology partner EIVA, explains all in this edition of The Watch.

“The ViperFish is a new surveying platform that we developed to address the growing demand for unexploded ordnance (UXO) surveying in the offshore wind industry,” said Kristensen. “It is a versatile and easy-to-use system that can be deployed from a vessel of opportunity. Expeditionary MCM survey requirements are very similar so navies can benefit from all our commercial experience to make their surveys far more efficient.”

Experience where it counts

“We wanted to incorporate all the lessons we learned from building and operating the ScanFish ROTV, the industry’s leading UXO survey platform, into the design of the ViperFish, creating a UXO surveying platform optimized to meet the demands of our customers. These include increasingly efficient surveys and where possible these needed to be automated. To support an increasing volume of surveys, new ROTVs needed to be compact, easy to launch and recover from a variety of vessels, including uncrewed surface vessels (USVs), and equipped with class-leading payloads and navigation sensors.

The system is built using the same building blocks as the ScanFish, enabling us to leverage all that experience. The first obvious difference between the ViperFish and the ScanFish is the shape. The ViperFish is cylindrical with actuated fins, while the ScanFish is shaped like an airfoil. The new system is as maneuverable, but the difference in shape offers a number of benefits:

- A lower drag coefficient: this means that it requires less power to tow. This is important for autonomous UXO surveys, as it allows the ViperFish to be deployed from smaller vessels or even from shore.

- More stability in rough seas: the pitch and roll are controlled by the actuators maintaining a more stable platform enabling you to work closer to the seafloor and maintain a stable platform at the sweet spot for the sensors providing improved data and therefore better decision making.

- A narrower profile enabling operations from smaller vessels: making it easier to transport and deploy. This is a major advantage for expeditionary surveys, as it allows the ViperFish to be deployed and recovered more quickly and easily.

It’s not just the platform. It’s the whole system. We conducted significant research to minimize the cable drag. By doing this, we can operate with smaller winches and deploy from a smaller surface area. We offer two shipment options: a self-contained cradle-box that can be shipped everywhere, or a container ready to integrate into a vessel.

It’s taken some time, but one of the most memorable things about the ViperFish is the first time we put it in the water,” said Kristensen. “On our first prototype test, we were out sailing 3 days and we had 100% uptime on the system. It was really a relief and a joy to see that all of our hard work had paid off.”

All the payloads

The ViperFish is equipped with all the sensors typically required on an ROTV, including:

- Solstice multi-aperture sonar: Used to create a two-dimensional image of the seabed. This image can be used to detect mine-like objects. The ViperFish uses the Solstice from our technology partner Wavefront Systems. This sonar is known for its high resolution and low power consumption.

- R2Sonic 2020 multibeam echosounder: It creates a three-dimensional image of the seabed. This is used to fill the gap ensuring 100 % coverage from a single survey line.

- OFG Hypermag: This magnetometer detects magnetic anomalies in the water or on the seabed generated by mines or other metallic objects while filtering out magnetic anomalies generated by the ViperFish itself.

- SPRINT-Nav Mini hybrid DVL-INS: Used to track orientation, position and speed; this system is from our technology partner Sonardyne. This information is used to create accurate maps of the survey area.

- Mini-Ranger 2 USBL positioning: The ultra-short baseline positioning system is used to track the ViperFish’s position in absolute coordinates. The Mini-Ranger 2 is a class-leading positioning system from our technology partner Sonardyne.

- Valeport sound velocity sensor: the sensor is used to optimize the sonar survey in real time, which is especially important when operating close inshore and within estuaries where sonar conditions can change rapidly.

The integration of these sensors into the ViperFish ROTV makes it a versatile and efficient UXO surveying platform. The ViperFish can be used to conduct surveys in a variety of conditions, and it can detect a wide range of objects.

Low-logistics, simple to operate, quick to train

“The ViperFish is operated by a crew of two people. The survey plans are prepared beforehand using NaviSuite Kuda software from EIVA. When launching the system, one person is responsible for supervising the ViperFish, while the other person controls the crane. At a speed through water of 2 to 10 knots, once in the water the ViperFish automatic controls take over, quickly swimming to the appropriate height from the seafloor within less than a minute. When the system is deployed one person is responsible for monitoring the automated mission while operating the ViperFish’s sensors and collecting data. If the ViperFish detects a possible UXO, the crew can mark the location on a map. The crew can then return to the location at a later time to investigate further. The system follows the seabed at a fixed height and can cope with slopes of up to 45 degrees. Plus it can replan its mission if obstacles are detected and avoid them in a safe manner while still obtaining high-quality data. When the mission is completed, the ViperFish is recovered by the two-person crew. We are also in discussions with USV manufacturers to make the launch and recovery totally automated.”

“The system is relatively easy to operate, even for people who are not trained hydrographers. The whole training process can be completed in a couple of weeks, it is mostly focused on learning how to set up the system and how to operate the sensors. If the crew is already experienced with using autonomous underwater vehicle (AUV) systems or the ScanFish, the training process will be a couple of days at most. Since the user interface of NaviSuite Kuda, EIVA’s survey software, is used widely in the commercial sector, there is already a large pool of contractors and trainers ready to support operations. In addition, sailors will be gaining valuable skills to support their transition to the commercial sector.”

Actionable data

“Ultimately, it’s about delivering our customers the best data, and you’ll be surprised how challenging it is to get these many payloads into the right form factor. But it has been worth it. We offer an incredible amount of area coverage rate of actual actionable data using class leading sensors.”

Please contact us to find out more.